Fire-proof printable Photoluminescent film- R06 Series

PRODUCT SERIES: Photoluminescent film

| Brand | YEEMAX |

| Origin | Fujian Quanzhou |

| Supply Ability | 50,000 ㎡/month |

| Minimum Order Quantity | 40 roll a pallet |

| Weight | 33kg |

| Dimensions | 1290*235*235(mm) |

| Warranty | 10years |

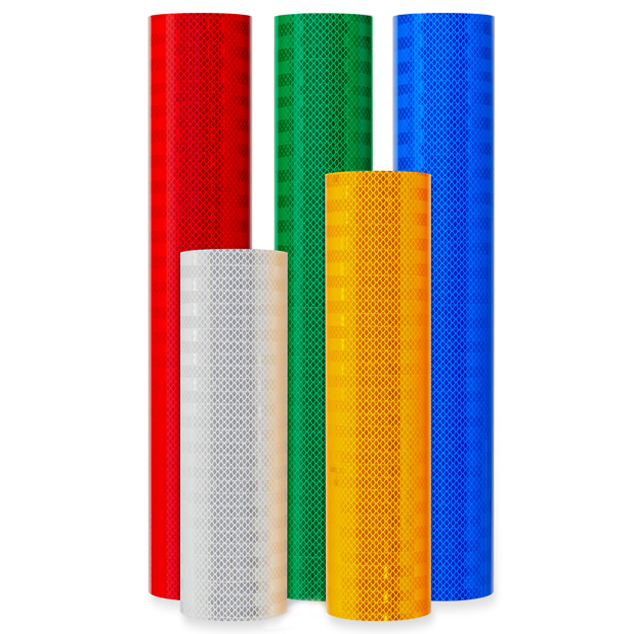

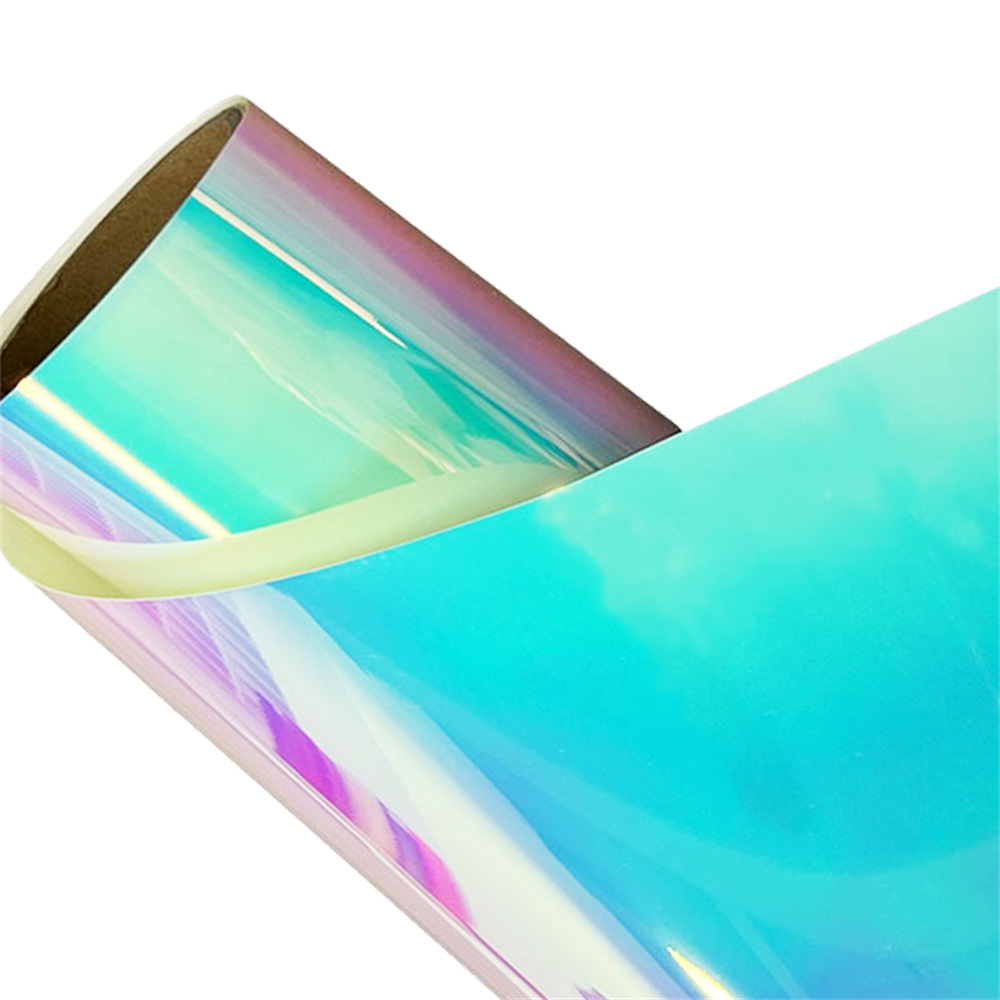

Color:

-

Product Description

The Flame-Retardant Photoluminescent Film is a high-performance safety film based on PVC substrate, combining photoluminescent technology with flame-retardant properties. This product has passed environmental certifications (including SGS) with heavy metal and phthalate tests complying with European standards (RoHS, REACH). It features excellent nighttime luminescence and fire safety protection capabilities, offering 5-7 years of weather resistance and supporting high-precision printing for safety signage and emergency indication systems in demanding environments.

Key Features

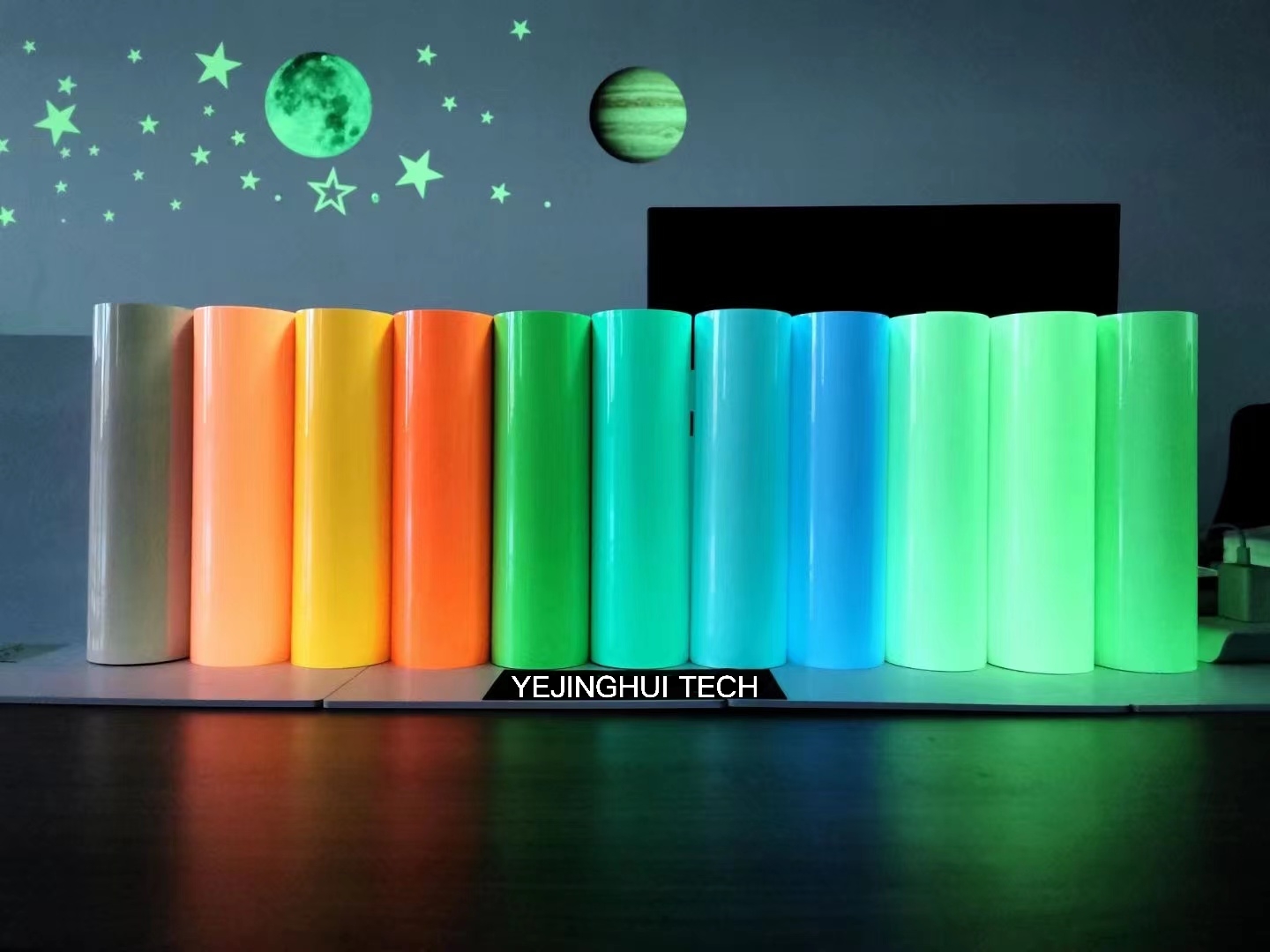

Photoluminescent Properties:

Absorbs visible light (natural or artificial) for 10-30 minutes, providing continuous illumination for 8-12 hours in darkness. Primarily available in yellow-green (other colors optional), with initial brightness exceeding 1200 mcd/m² (within 1 minute), significantly enhancing visibility in low-light conditions.Flame-Retardant Safety:

Certified by DNV (Det Norske Veritas) and other international testing standards, achieving B2 or higher flame-retardant rating (e.g., UL94 V-0). Self-extinguishes when exposed to fire sources, preventing flame spread and minimizing burning drips.Environmental Adaptability:

Resistant to salt spray, detergents, and extreme temperatures (-20℃ to +50℃), suitable for harsh environments including marine, tunnel, and industrial facilities.Printing Compatibility:

Supports screen printing, solvent-based inkjet printing, and digital printing for customized labels and patterns.

Technical Specifications

Attribute Description Brand Flame-Retardant Photoluminescent Film Series (custom branding available) Adhesive Type Acrylic pressure-sensitive adhesive (high tack, weather-resistant) or custom non-adhesive versions Durability 5-7 years outdoor weather resistance; UV stable; temperature resistant (-20℃ to +50℃); chemical corrosion resistant Processing Suitable for die-cutting, slitting, printing; compatible with digital and screen printing; stamping or laser engraving capable Applications

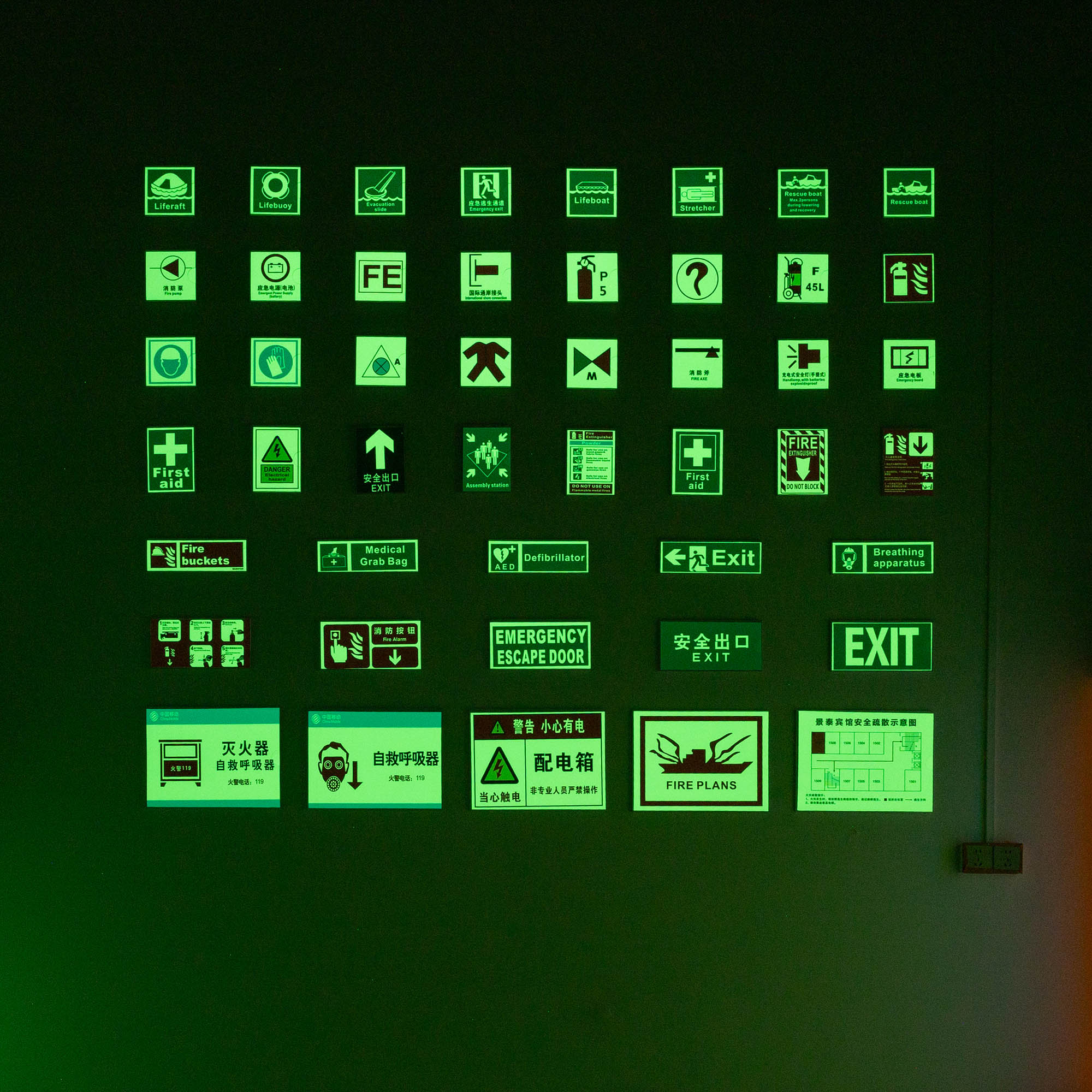

Marine & Offshore Engineering: Marine safety signs, life-saving equipment labels, fire control labels (DNV certified).

Transportation & Tunnel Safety: Emergency escape indicators for highway tunnels, subway evacuation signs, fire exit markings (light penetrates smoke).

Industrial & Public Facilities: Warning signs for oil platforms, power facilities, chemical plants; emergency exit indicators for hospitals and shopping malls.

Smart Cities & Construction: Integrated into smart fire protection systems, EV charging station labels, dynamic safety warning signs.

Certifications & Compliance

Environmental Certification: SGS tested, compliant with RoHS, REACH, EN71 standards (heavy metal and phthalate free).

Safety Certification: DNV marine certification, DIN67510 Part 1 luminescence standard, UL94 flame-retardant rating.

Performance Testing: Saltwater resistance, detergent resistance, abrasion resistance; luminescence performance maintained (>0.32 mcd/m² for up to 25 hours).

Why Choose Flame-Retardant Photoluminescent Film?

Dual Safety Assurance: Combines photoluminescence and flame-retardant properties to address both fire and low-light risks.

Long-Lasting Durability: 5-7 year service life reduces maintenance costs.

Customization Flexibility: Supports size, color, and printed pattern customization for diverse scenarios.

Global Compliance: Meets European and international standards, suitable for export markets.

Environmentally Friendly: Non-toxic and non-radioactive, safe for public spaces.

Note: The above data is based on industry standards and typical application scenarios. Specific parameters can be supported by test reports and sample validation according to customer requirements. For DNV certification documents or SGS test details, please contact our technical support team.

Description

Our company independently researches and produces photoluminescent (phosphorescent) film, which is primarily composed of natural rare earth elements combined with various materials. It utilizes the principle of rare earth natural absorption and luminescence, environmentally friendly with no radiation, and offers long-lasting phosphorescent luminescence. This film is used in various applications, including fire safety signs, maritime IMO signage, decorative wall decals, phone cases, luminescent photo paper, and more.

Product Data

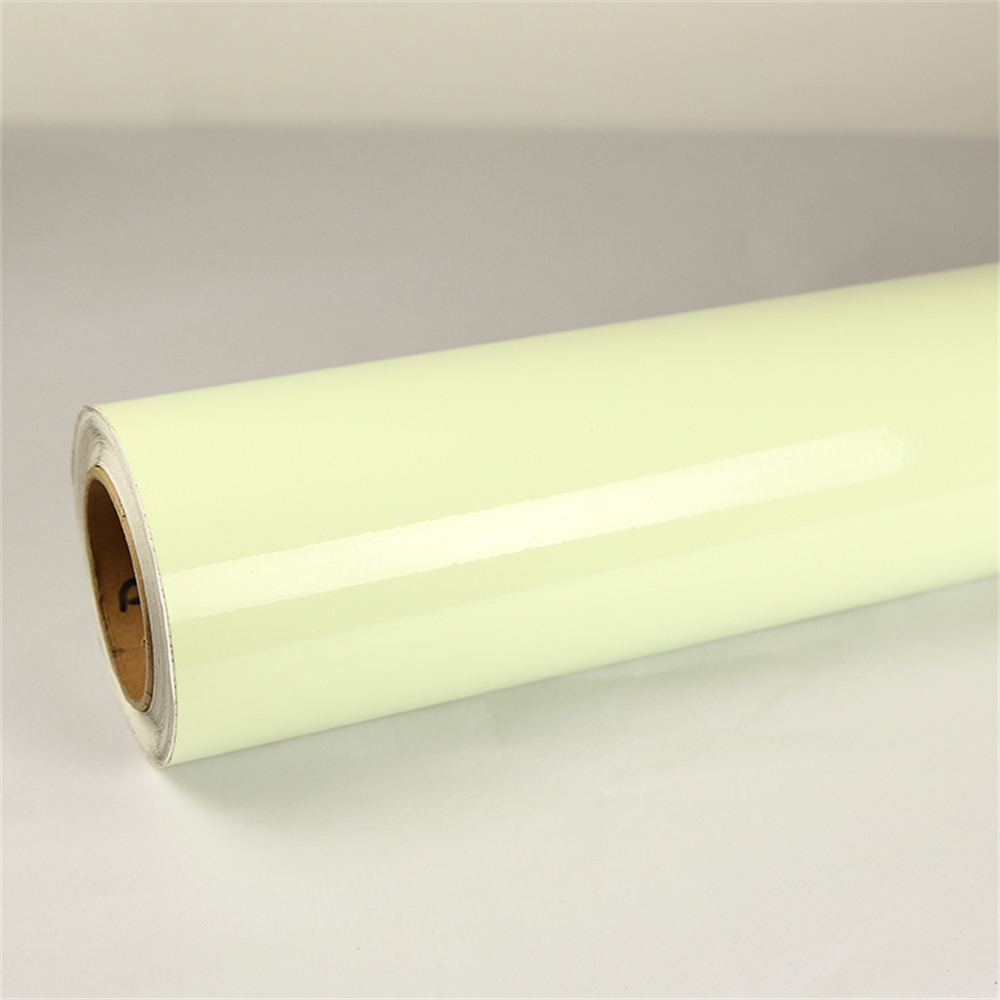

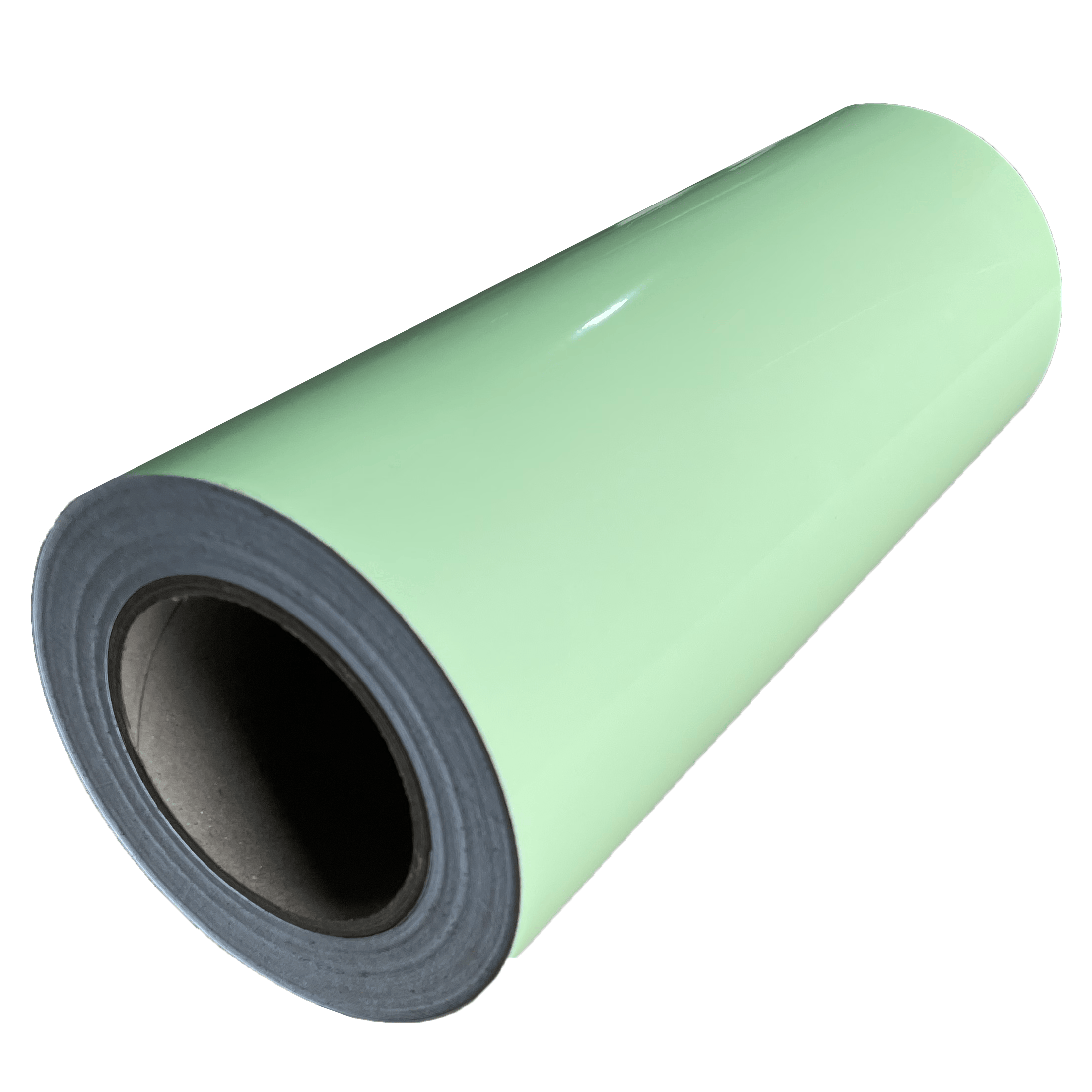

Visual Appearance: Glossy appearance, light yellow green color

Adhesive: Permanent pressure sensitive

Size: 1.24m (Width), 45.7m (Length)

Application Surface: Flat, simple curves

Application Temperature Range: 50°F to 100°F Or 10°C to 38°C

Service temperature range: -4°F to 120°F -20°C to 50°C

Luminance Characteristics

The afterglow of luminous film degrades with time once the charging source is removed. This characteristic must be taken into account when designing and locating signs and markings. The amount of afterglow visibility (luminance level) depends upon the observation conditions such as ambient light, observer, etc.

Item

Thickness(mm)

(mcd/㎡)

Glowtime

Material

Film thickness

(including glue)Tatal Thickness

10 min

60min

YJHNW-R02

0.23

0.37

55

7

>500mins

PVC

YJHNW-R04

0.25

0.39

100

12

>694mins

PVC

YJHNW-R06

0.28

0.42

160

20

>940mins

PVC

YJHNW-R08

0.3

0.44

210

25

>1077mins

PVC

YJHNW-R10

0.32

0.46

260

35

>1293mins

PVC

Product performance

1. The luminous film made of PVC plastic has certain flame retardant properties. The product is flame retardant.

2. It has certain resistance to salt water and detergent (can be cleaned with detergent).

3. It has excellent heat resistance and cold resistance and can be used in environments of -20~50℃.

4. The luminescent film has good physical and mechanical properties, excellent weather resistance, and an outdoor life of 3 to 5 years and an indoor life of 5 to 7 years.

5. The luminescent film is instant-on and can be attached to the surface of general objects.

6.Passed 17P, phthalate and other tests. Possess SGS, RoHS and other reports. Use environmentally friendly materials, no phthalate and heavy metals.

Usage methods and precautions:

1. Construction should be carried out on a flat surface, and the construction temperature should be 10~38℃.

2. The luminous film can be cut into various shapes and directly pasted somewhere to play a decorative and instructional role.

3. Silk-print patterns, text, etc. on the surface of the luminescent film to form a light-emitting substrate.

4. Before attaching it to the surface of the object, the surface of the object should be cleaned first. There should be no oil, dust, etc. on the surface.

5. This luminescent film has a certain degree of thermal expansion and contraction. The sliced luminescent film cannot be placed randomly. It should be clamped or pressed with heavy objects to prevent deformation and curling.

6. When using, remove the release paper on the back of the luminescent film, apply a certain amount of pressure to the luminescent film and stick it flatly on the surface of the treated object, paying attention to the corners.

7. The same type of luminous film will have certain color differences in different batch numbers to ensure luminous brightness.

8. Luminous film rolls longer than 10M may have joints.

9. Dust will accumulate on the surface of the luminescent film for a long time, which will affect the luminous brightness. It is recommended to clean the surface with a clean cloth regularly. Solvents are prohibited. Wipe the surface of the luminous film, use a small amount of water to clean it and prevent water from entering the back and causing the product to fall off.

Packaging and storage

1. Packaging: roll or sheet form, external plastic film packaging, external packaging carton.

2. Storage: It should be stored in a ventilated, dry and cool warehouse, with a storage temperature of 10~28℃ and a relative humidity of 30~70%.