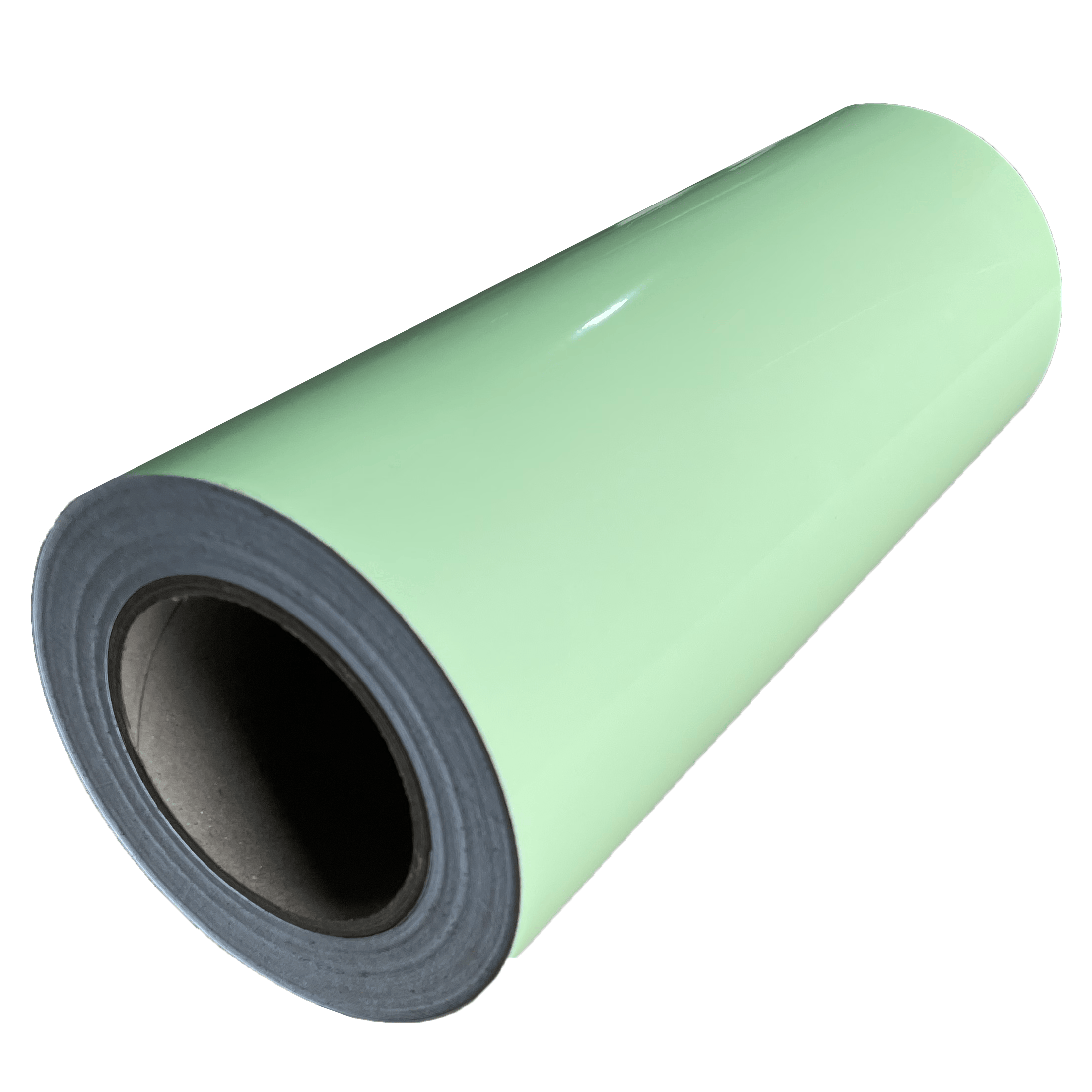

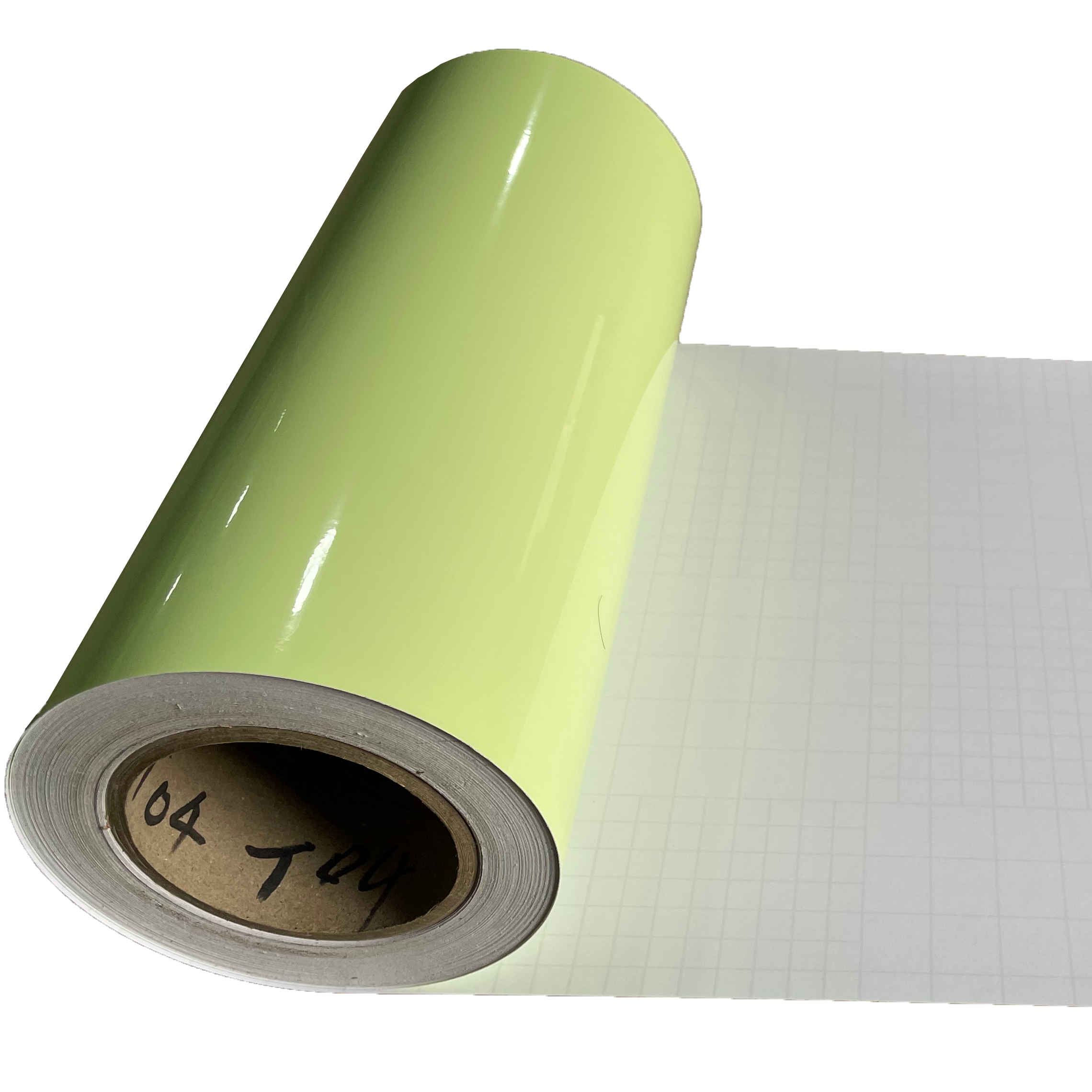

Self Adhesive PVC Photoluminescent Film

PRODUCT SERIES: Photoluminescent film

| Brand | YEEMAX |

| Origin | Fujian Quanzhou |

| Supply Ability | 300,000 ㎡/month |

| Minimum Order Quantity | 40 roll a pallet |

| Weight | - kg |

| Dimensions | 1,290*215*215(mm) |

| Durability | 5-7 years |

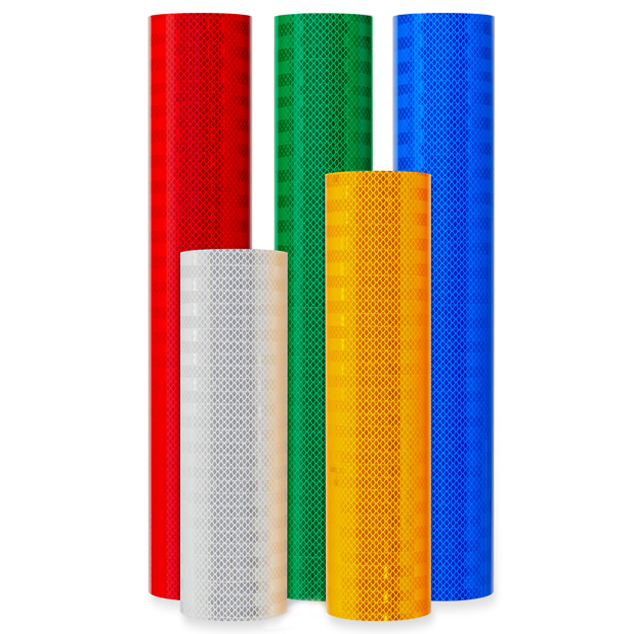

Color:

-

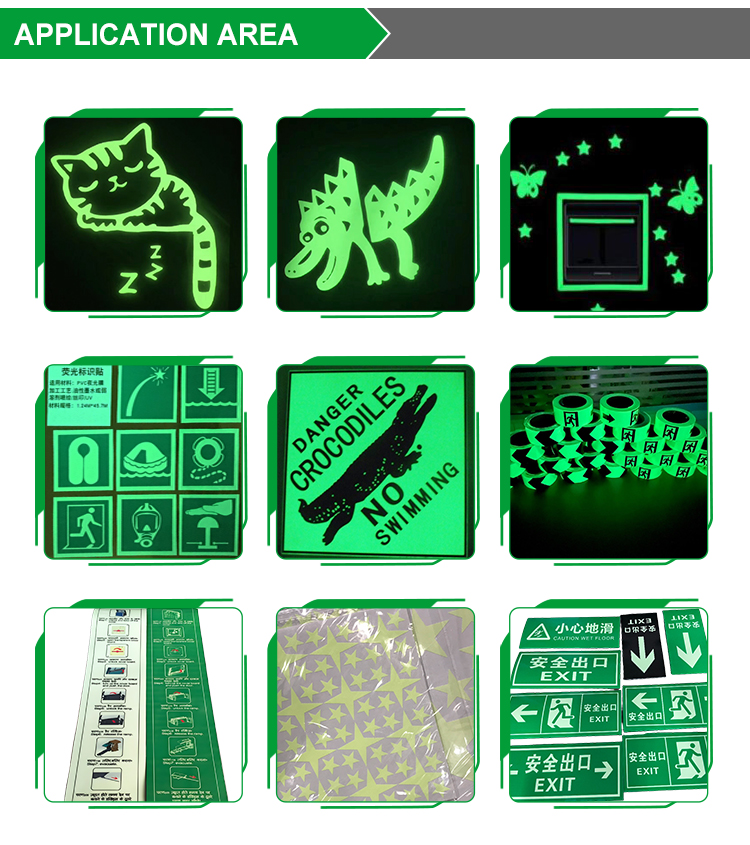

Our company independently researches and produces photoluminescent (phosphorescent) film, which is primarily composed of natural rare earth elements combined with various materials. It utilizes the principle of rare earth natural absorption and luminescence, environmentally friendly with no radiation, and offers long-lasting phosphorescent luminescence. This film is used in various applications, including fire safety signs, maritime IMO signage, decorative wall decals, phone cases, luminescent photo paper, and more.

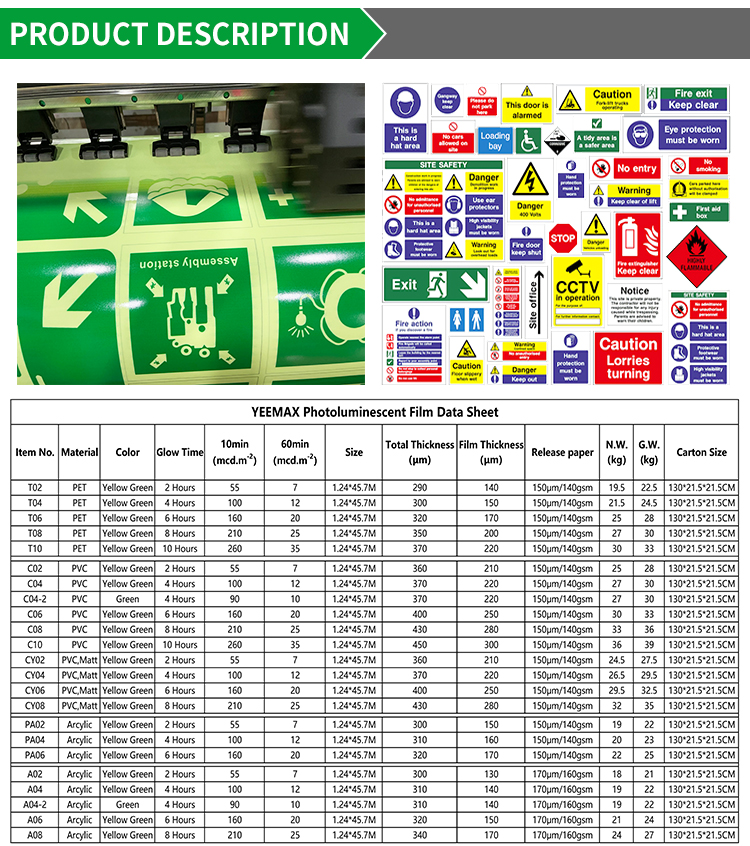

Product Data

Visual Appearance: Glossy appearance, light yellow green color

Adhesive: Permanent pressure sensitive

Size: 1.24m (Width), 45.7m (Length)

Application Surface: Flat, simple curves

Application Temperature Range: 50°F to 100°F Or 10°C to 38°C

Service temperature range: -4°F to 120°F -20°C to 50°C

Luminance Characteristics

The afterglow of luminous film degrades with time once the charging source is removed. This characteristic must be taken into account when designing and locating signs and markings. The amount of afterglow visibility (luminance level) depends upon the observation conditions such as ambient light, observer, etc.

Item

Thickness(mm)

(mcd/㎡)

Glowtime

Weight

Material

Film thickness

(including glue)Tatal Thickness

10 min

60min

(g/㎡)

YJHNW-C02

0.23

0.37

60

8

>500mins

425±10

PVC

YJHNW-C04

0.25

0.39

107

14

>694mins

440±10

PVC

YJHNW-C06

0.28

0.42

172

21

>940mins

500±10

PVC

YJHNW-C08

0.3

0.44

230

28

>1077mins

550±10

PVC

YJHNW-C10

0.32

0.46

258

34

>1293mins

590±10

PVC

Product performance

1. The luminous film made of PVC plastic has certain flame retardant properties.

2. It has certain resistance to salt water and detergent (can be cleaned with detergent).

3. It has excellent heat resistance and cold resistance and can be used in environments of -20~50℃.

4. The luminescent film has good physical and mechanical properties, excellent weather resistance, and an outdoor life of 3 to 5 years and an indoor life of 5 to 7 years.

5. The luminescent film is instant-on and can be attached to the surface of general objects.

Usage methods and precautions:

1. Construction should be carried out on a flat surface, and the construction temperature should be 10~38℃.

2. The luminous film can be cut into various shapes and directly pasted somewhere to play a decorative and instructional role.

3. Silk-print patterns, text, etc. on the surface of the luminescent film to form a light-emitting substrate.

4. Before attaching it to the surface of the object, the surface of the object should be cleaned first. There should be no oil, dust, etc. on the surface.

5. This luminescent film has a certain degree of thermal expansion and contraction. The sliced luminescent film cannot be placed randomly. It should be clamped or pressed with heavy objects to prevent deformation and curling.

6. When using, remove the release paper on the back of the luminescent film, apply a certain amount of pressure to the luminescent film and stick it flatly on the surface of the treated object, paying attention to the corners.

7. The same type of luminous film will have certain color differences in different batch numbers to ensure luminous brightness.

8. Luminous film rolls longer than 10M may have joints.

9. Dust will accumulate on the surface of the luminescent film for a long time, which will affect the luminous brightness. It is recommended to clean the surface with a clean cloth regularly. Solvents are prohibited. Wipe the surface of the luminous film, use a small amount of water to clean it and prevent water from entering the back and causing the product to fall off.

Packaging and storage

1. Packaging: roll or sheet form, external plastic film packaging, external packaging carton.

2. Storage: It should be stored in a ventilated, dry and cool warehouse, with a storage temperature of 10~28℃ and a relative humidity of 30~70%.

------------------

1. Core Technology Advantages

Photoluminescent Coating and Printing Compatibility

The composite process of rare earth aluminate light-storing material and PVC resin is adopted. The surface layer is a highly ink-absorbent PVC polymer material, which supports UV inkjet printing, solvent-based inks, and screen printing. The color saturation of the inkjet printing surface is more than 95%, and the annual fading rate is less than 10%. The luminous layer can continuously emit light for 2-12 hours (depending on the product grade) after absorbing light for 10-30 minutes, with a brightness of ≥55mcd/m² (DIN 67510 standard), and the nighttime visual distance is increased by 300%.

Technical highlights: The fusion process of luminous powder and PVC resin has a fine surface without granularity, and the ink has strong adhesion, avoiding the problem of easy shedding of traditional luminous powder.

2. Scenario-based Application Innovation

Commercial Advertising and Safety Signs

Safety emergency signs: fire channel guide stickers, industrial equipment warning tapes, which can still be identified at a distance of 20 meters after power failure, complying with EN ISO 7010 safety certification.

Creative Design and Intelligent Integration

Cultural and creative customization: supports 0.1mm ultra-fine pattern cutting;

Smart home linkage: cooperate with the lighting system, store energy during the day/slowly release light at night, reducing energy consumption by 90% (case: smart community corridor guidance system).

3. Production Services and Customization Capabilities

Fully Automatic Precision Processing

Equipped with German Kurz coating line (speed 60m/min), supports 1.24m×50m standard coil and 5cm narrow strip slitting, slitting accuracy ±0.05mm, yield rate ≥98%.

Flexible Customization Solution

Luminous intensity grading: Provide products with corresponding standards of DIN67510 at different levels, and can also be selected according to the duration of luminescence to adapt to different scene requirements;

Quick response mechanism: deliver small batch orders within 48 hours, and keep 1000+ rolls in stock.

4. Environmental Protection and Economic Benefits

Green Production Process

Passed REACH and RoHS certification.

Long-Term Photoluminescent Coating Cost Reduction Value

Maintenance-free design: No power and circuit maintenance is required, and the operation and maintenance cost of traditional light boxes is reduced by 70%;

Ready to use: Strong adhesive backing, supports multiple substrates such as tiles, glass, and metal, and construction efficiency is increased by 50%.

Core technology advantages

1. Glass microbead precision coating process

Using a composite structure of PET substrate and high-refractive index glass microbeads, 360° wide-angle reflection is achieved through micron-level precision coating, and the nighttime visible distance is increased by 40%, meeting the ISO 20471 temporary identification standard. Compared with traditional products, the reflective brightness is increased by 3 times.

2. Super strong environmental adaptability

Multi-layer composite structure, outdoor weather resistance of 1-3 years, in line with the service life of advertising material scenes.

3. Production strength and customized services

Support 12 standard colors (including fluorescent orange/green) and two-color twill/straight customization (minimum strip width 5cm), 48-hour delivery of emergency orders (stock always 500+ rolls), to meet personalized needs such as advertising signs and car body stickers.